Zirconia

ZIRCONIA MACHINING & GRINDING

Zirconium Dioxide (ZrO2), also known as zirconia, is a metallic oxide. It can be processed from the mineral Baddeleyite or extracted from zirconium silicate sand.

Zirconium dioxide (ZrO2) is a great ceramics material due to its very high resistance to crack propagation and very high thermal expansion properties. This makes it great for joining ceramic and steel together.

Its main benefits are low thermal conductivity, high corrosion resistance, high strength, high wear resistance, and oxygen ion conduction–all of which are positive attributes to have in ceramic applications. The material is significantly more expensive compared to other ceramics.

Zirconia is used for a number of different applications due to its unique properties. It is commonly used in tools for wire forming. It’s also an essential material in dental crowns and bridges, a main material in insulating rings for thermal processes, and much more.

APPLICATIONS

- It can be added to non-oxide ceramics as a sintering aid.

- It can be added to glaze formations and body for increased hardness of a final product.

- It can be used in crucibles, vales, and nozzles to prevent melting from projects involving molten metals.

- It can make transparent materials white being used as an opacifier in glaze mixtures, and can also be used as a whitening agent where porcelains are involved.

- It can be used in abrasives and cutting tools because of its chemical and corrosion resistance.

- It can be used in medical implants due to its porosity.

Machining Properties

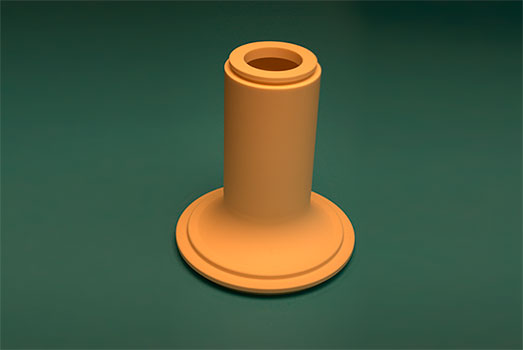

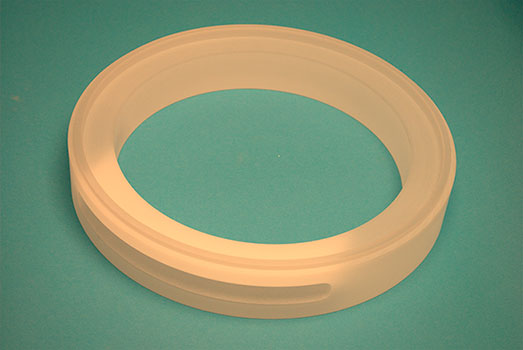

It can be difficult to manufacture zirconia in large quantities compared to other materials. In addition, zirconia is a relatively expensive material, and its use is usually limited to small parts or small components. Zirconia is used in components that require resistance to fracture, chipping, cracking, and also have high bending strength. Some common zirconia items that are often machined are clamps, cylinders, nozzles, bearings, plates, rods, pistons, pumps, and cutting discs.

Zirconia starts out as granular powder, and is then mixed with other stabilizers and binders to give the desired characteristics in the end product. The material can be formed using a number of possible methods like isostatic pressing, extrusion, injection molding, or mechanical pressing.

If the final ceramic products are tubes, rods, or barstock materials, extrusion is the preferred method. This process involves forcing the zirconia material through a precisely engineered die.

Injection molding is another method used mainly for intricate or high-volume ceramic components. And finally, mechanical pressing is used to create a net or net-like shape.

After formation, zirconia must be sintered at high temperatures in gas or electric kilns for long periods of time. The typical firing temperatures for zirconia range from 2,850º F to 3,100º F, and length of time ranging from 12 to 120 hours.

Custom Zirconia Ceramic Products

If you are looking to use zirconia in your ceramics, Applied Ceramics has the experience to precisely grind and machine zirconia into the shapes, sizes, and forms you need. Our skilled technicians have extensive experience machining zirconia into cylinders, blocks, linings, discs, plates, and more.

From intricate shapes, to specific thermal properties, to corrosion-resistant zirconia ceramic applications, we have the skill and equipment to meet your specifications.

Contact us to discuss your application and learn more about our process to deliver the product you need.

APPLICATIONS

- Ceramic tubes

- Bearings

- Cutters

- Dental ceramics (Crowns/Bridges)

- Pumps, seals, & seal rings

- Valves

- Substrates

MAIN PROPERTIES

- Excellent resistance to chemicals and corrosion

- Excellent strength

- High resistance to crack propagation, and highly resistant against fractures

- High density, high wear resistance, and good frictional behavior

- High thermal expansion capabilities up to 2,400ºC

- Elasticity similar to steel and non-magnetic

- Low thermal conductivity and excellent thermal insulation

-

Zirconia

Properties Units Zirconia MECHANICAL Density g/cm3 5.79-6.05 Color – ivory Water Absorption % 0 Flexural Strength MPa@room temp.(R.T.) 900-980 Compressive Strength MPa@R.T. – Hardness GPa 11.0-12.7 THERMAL Coefficient of Linear Thermal Expansion 1E-6/°C

(»25°C to Ј1000°C)9.2-10.3 Thermal Conductivity W/m°K@R.T. 2.2-3.8 Specific Heat cal/g°C@R.T. 0.12 Thermal Shock Resistance D T(°C) 280-360 Maximum Use Temperature °C 2400 ELECTRICAL Volume Resistivity Ohm. cm@R.T. – Dielectric Constant 1MHz@R.T. –